【Excerpts】Mechanical equipment is commonly used for bored piles

Browse services

- Petroleum and Gas

- 【Excerpt】High pressure jet grouting construction technology

- 【Excerpt】How to construct slope anchor cable?

- HDL-60S multi-function drilling rig shipped to Singapore

- 【Excerpt】Why do we need to test piles before pile foundation construction?

- We are the one-stop construction problem solver

- 【Holiday arrangement】Dragon Boat Festival

- 【Excerpt】The "Seven-Character Guideline" for Ground Treatment: A Comprehensive Interpretation!

- 【Excerpt】What is the difference between cement mixing pile and high pressure jet pile?

- 【Construction Case】HDL-200C top drive drilling rig for water stopper curtain of overseas dam

- 【Excerpt】What to do with a broken pile

- Holiday arrangement

- Our Drilling Rig: Client Success Story

The common construction machinery and equipment of bored pile include rotary drilling machine, impact drill machine, rotary drilling machine, truck crane, mud pump, excavator, electric welding machine, butt welding machine, etc.

1、Rotary drilling rig

Rotary excavation drill is a kind of construction machinery suitable for forming holes in construction foundation engineering. Widely used in municipal construction, highway bridge, high-rise building foundation construction engineering, with different drilling tools, adapted to dry (short spiral), or wet (rotary) and layer (core drill) hole operation, rotary drilling rig with large installed power, large output torque, axial pressure, flexible, high construction efficiency and multi-function characteristics. The rotary drilling rig ADAPTS to the soil geological conditions in most areas of China, using a wide range, basically can meet the use of bridge construction, high-rise building foundation and other projects. At present, rotary drilling rig has been widely promoted in a variety of bored pile projects.

At present, most of the rotary drilling rigs in Chinese engineering field are the products of Germany and Italy, and have occupied the dominant position.

The main domestic manufacturers are Xugong Machinery, Shanhe Intelligence, Sany Heavy Industry, Zoomlion and so on.

rotary drilling rig

2、Commonly used percussion drilling rig

The vertical reciprocating movement of the drill tool makes the drill bit impact the bottom of the well to break the rock layer. Its structure is simple, no circulation well washing system, debris removal and drilling rig can not be carried out at the same time, so the effect is low. There are two main types:

① punch cone. Impact on the formation with the weight of the drill tool itself. The lower end of the drill is several pointed blades that can be closed. When the drill moves downward under its own weight, the blade opens and cuts into the rock layer. Then lift the drill through the wire rope and grab the debris into the cone in the closing process, and the wellhead is proposed to discharge the debris. The drilling depth is usually 40 to 50 m and the deepest is 100-150 m.

② Wire rope impact drill. It is composed of mast and lifting pulley, wire rope, impact mechanism, drilling tool, motor, etc. During the operation, the motor drives the impact mechanism through the drive device, and drives the wire rope to make the drill tool move up and down. When the motor moves downward, the weight of the bit itself cuts into and breaks the rock layer, and the upward movement is pulled by the wire rope. Impact frequency is 30~60 times / min.

percussion drilling rig

3、Commonly used rotary drilling rig

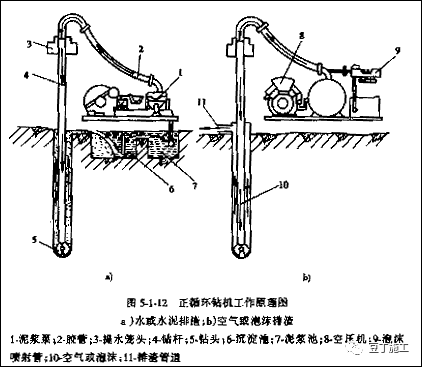

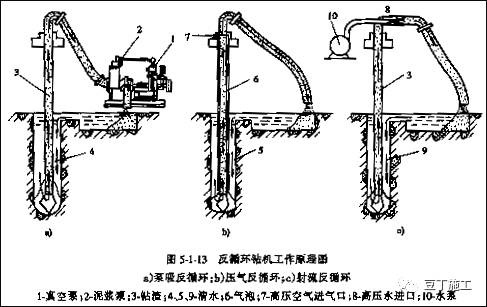

① Cycle mud washing well rotary rig. It consists of tower, winch, rotary table, drilling tool, mud pump, faucet and electric motor. During the operation, the power engine drives the turntable through the transmission device, and the active drill rod drives the drill bit to rotate the broken rock layer. There are two kinds of positive and negative cycles. When the positive circulation drill is working, the cuttings at the bottom of the well are taken out of the wellhead through the ring channel outside the drill pipe. After the sedimentation tank settles, the mud flows back to the mud pool for recycling. When the reverse cycle drilling rig works, the mud flows into the bottom of the well from the sedimentation tank, and the mud carrying debris is pumped out of the well through the sand pump through the drill pipe through the inner mouth of the drill pipe, and sinks to the sedimentation tank. The drill forms a high rising velocity in the drill pipe, the ability to discharge debris and pebbles is strong, and the drilling speed is fast, which is suitable for soil layer, sand layer and pebble diameter smaller than the inner diameter of the drill pipe.

② Pressure gas washing well rotary type drill. Use air compressor instead of mud pump and compressed air to wash the well. Usually use the reverse circulation mode, also known as the air lift reverse circulation. It is suitable for dry areas and cold permafrost with large well depth and water shortage.

rotary drilling rig

Operating principle of positive cycle rig (shown below). Drg by motor drive rotary drill pipe, rotary drilling, and start the mud pump on mud pool mud pressure through the hose, faucet, hollow pipe, finally from the drill bottom, wash the bottom, and the mixed with mud slag rise along the wall rise through the hole outlet, into the circulation pool. After the drilling slag is deposited, the cleaner mud flows back to the mud pool, thus forming a working cycle.

Working cycle of the reverse loop rig (shown below). The working mud cycle of this kind of drilling rig is opposite to the positive circulation direction. The mud with mixed slag enters the mud pump through the drill bit, hollow drill pipe, lifting water head and hose, and then flows from the pump valve into the mud pool, and then the mud is precipitated and then flows to the hole well.

4、Car hanging

Motor crane is mainly used for hoisting of steel cage, rig displacement, concrete pipe and other materials; mainly according on the weight of steel cage and the actual lifting condition on site.

5、mud pump

6、Other equipment

Excavator, electric welding machine, butt welding machine, etc.

——Source: Geotechnical Engineering Market

Disclaimer: We respect originality and share it, and appreciate the hard work and creativity of each author. We are committed to protecting the copyright of authors, the sources of content have been marked with the source, only for knowledge dissemination and sharing, no other commercial profit role, if there is any infringement, please contact us to remove.