【Excerpts】High-pressure rotary jet prestressed anchor cable support construction method

Browse services

- Petroleum and Gas

- 【Excerpt】High pressure jet grouting construction technology

- 【Excerpt】How to construct slope anchor cable?

- HDL-60S multi-function drilling rig shipped to Singapore

- 【Excerpt】Why do we need to test piles before pile foundation construction?

- We are the one-stop construction problem solver

- 【Holiday arrangement】Dragon Boat Festival

- 【Excerpt】The "Seven-Character Guideline" for Ground Treatment: A Comprehensive Interpretation!

- 【Excerpt】What is the difference between cement mixing pile and high pressure jet pile?

- 【Construction Case】HDL-200C top drive drilling rig for water stopper curtain of overseas dam

- 【Excerpt】What to do with a broken pile

- Holiday arrangement

- Our Drilling Rig: Client Success Story

With the development of urban construction, land began to become nervous, make people constantly development of underground area, deep foundation pit project everywhere, underground space technology, rock anchoring technology, complex soil envelope technology is more and more widely used, foundation pit depth is more and more deep, foundation pit wall with the existing buildings (road) spacing is more and more small, how to ensure the stability of the foundation pit, existing buildings (road) and the proposed building structure and operator safety, become the key project.

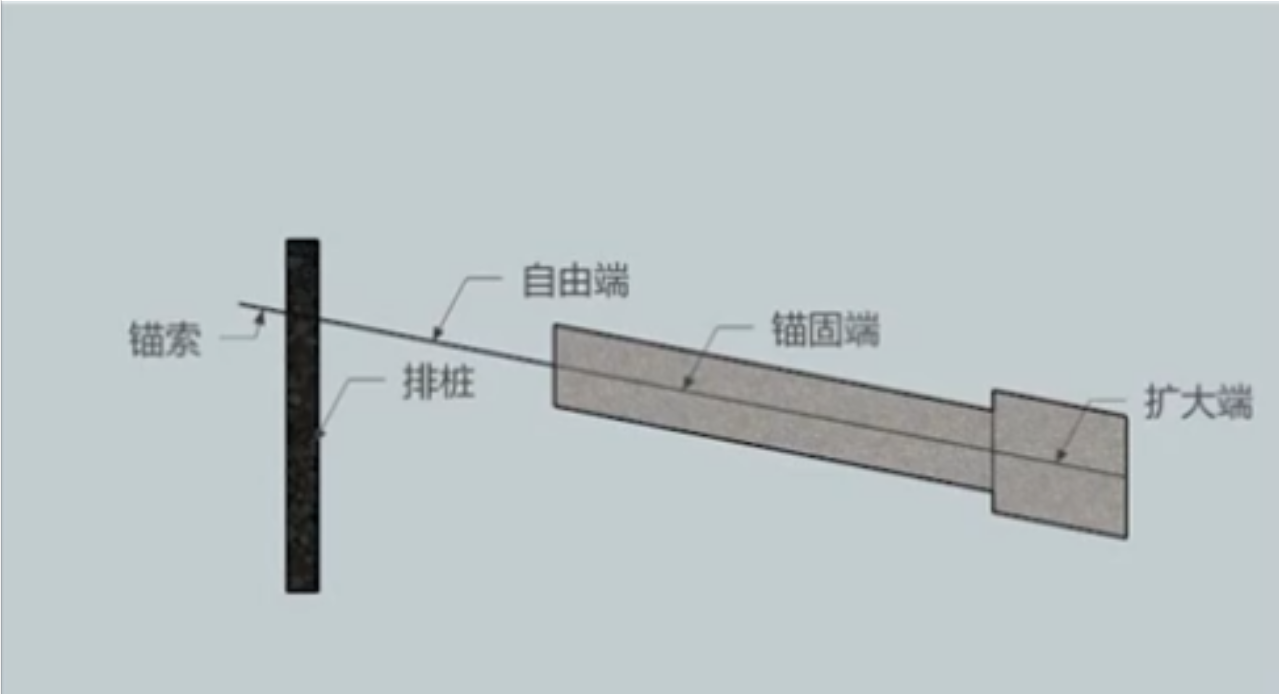

Prestressed anchor cable is a retaining structure used for soil excavation and slope stability. Through the application of high pressure rotary spray pre-stressed anchor cable for the difficult, unporous or slow drilling efficiency of the complex soil layer, and this construction method is summarized.

Construction characteristics

1、The large diameter of the anchor solid (generally 300-500mm) can effectively reduce the stress level of the soil around the anchor cable, reduce the plastic deformation of the anchor cable, and then through pre-tension, the displacement and internal force can effectively control the support structure, achieving the purpose of effective constraint deformation and reducing creep deformation.

2、The anchor solid diameter is large, and the end of the anchor solid can form the "expanded head" by stirring and increasing the slurry injection pressure. It has both conventional section and expanded head, which can effectively overcome the disadvantage of small side resistance of silt soil, and the anchorage force can be increased by 3~6 times compared with the conventional anchor cable.

3、During the construction of high pressure rotary jet prestressed anchor cable, hole forming, jet grouting, mixing and prestressed reinforcement placement are completed at one time, which can effectively overcome the collapse hole and neck shrinkage problems of the construction of the conventional anchor cable in the silt soil layer, and ensure the construction quality of the anchor cable.

4、The layout method is flexible and can adapt to the complex surrounding environment of the foundation pit. The required operation space is small, which can be set at any tilt Angle to replace the conventional anchors and soil nails, which is suitable for different geological and site conditions.

5、For the geology of silt soil and large water content, the high pressure rotary spray anchor cable can effectively prevent the problems such as hole formation and hole collapse, and ensure the bond strength of cement slurry and soil.

6、The system can actively provide skid resistance, increase the friction with the soil, and effectively control the displacement of the soil, so as to fundamentally improve the mechanical properties of the enclosure wall.

Scope of application

This method is applicable to all kinds of construction projects, highway engineering, water conservancy projects and other related deep foundation pit support, complex soil foundation pit support, and the deep foundation pit support works close to the existing buildings (structures).

Construction principle

High pressure rotary jet prestressed anchor cable is a kind of large diameter cement soil pile combined with traditional anchor cable of new anchor cable structure, it use rotary jet drill according to certain Angle in soil hole, injection cement slurry, fully mixing pile, at the same time using the drill bit steel strand into the pile, formed after high pressure rotary jet prestressed anchor cable.

Construction process and construction key points

1、Construction process: the construction process of hole forming, jet grouting, mixing and prestressed reinforcement placement should be used once. The specific process is as follows: Earthwork excavation→Adventitia line fixed hole position→The rig is in place→Correct the hole position and adjust the angle→Drilling (with anchor cable)→Jet grouting→Pulling tube→Install the waist beam and anchor head anchor tool→Tension lock

2、Construction points:

① earthwork excavation: anchor cable construction working face is determined according to the height of mechanical equipment, generally excavated to the 1~1.3m position below the hole position, this position is convenient for the mechanical placement of anchor cable.

② Anchor hole positioning: after the completion of the surface soil cleaning of the cast-in-place pile, the pile soil dressing and the surface steel bar hanging mesh grouting, the hole position shall be determined according to the design requirements of elevation and horizontal spacing, and marked with self-spray paint. After marking, cut out the round hole of about 150mm diameter in the surface grouting surface to facilitate the positioning of the drill bit and drilling into the soil layer. The anchor hole positioning error is less than 50mm, and the hole oblique error is less than ± 3 degrees.

Figure 5.2.2-1 After anchor hole positioning and drilling

③ The drilling rig is in position: align the drill at the hole position, adjust the Angle, check the drilling hole so that the hole opening error does not exceed ± 3 degrees, and the plane position (horizontal and vertical) error at the hole is ± 50mm. The drilling rig should be flat and stable to ensure that the equipment will not shake and change in position after the stress.

Figure 5.2.3-2 Drilling machine Angle plate

Figure 5.2.3-2 Drilling machine Angle plate

④ Drilling and anchor construction: select carbide high pressure rotary drill and set multiple nozzles on the side of the drill for high pressure rotary drilling process. The depth of bolt drilling shall not be less than the design length, nor be greater than the design length of 0.5m. After filtering in the mixing tank (bucket), the high pressure pump introduces the hollow screw pipe through the design depth and diameter to form the anchor body.

Figure 5.2.4-1 Mix cement slurry Figure 5.2.4-2 High-pressure rotary injection

anchor cable hole forming and grouting

⑤ Make and place the anchor cables

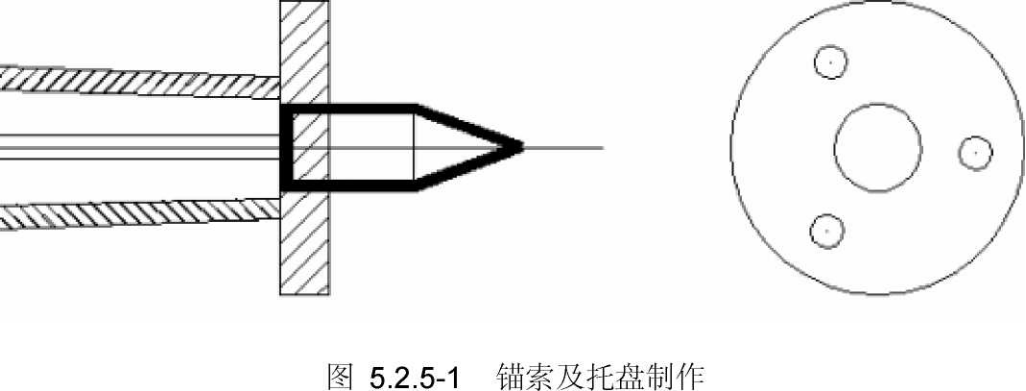

Steel strand is set according to the design requirements. The end head adopts Φ 15010 steel plate anchor plate, and the anchor head is welded and fixed with 18 # nut and anchor cable. Steel strand shall be placed on the center of the anchor body, with 0.7m for tension, feeding length of anchor cable = length of anchor cable anchorage section length + free section length + working section length. The assembled anchor cable enters the hole along with the drill pipe when drilling

Figure 5.2.5-1, anchor cable and tray making

⑥ Prestressed anchor cable tension and locking

The tension locking can be performed after the anchor is maintained for 10 days and the slurry strength reaches 80%. The tendon should be firmly connected with the waist beam and the anchor. The elongation value of the anchor cable should be measured synchronously with the magnetic displacement device, and the slip amount of the prestressed steel strand should be measured after locking. The stability time of each stage of tension must be guaranteed, and the double control operation method of tension control and value extension check should be adopted. The tension lock value is the design lock value. Use high pressure oil pump and heart piercing jack. The locking force should be monitored after the tension of the anchor cable. When the prestress loss is serious, the secondary tension must be conducted. After the tension, handle the steel strand outside the anchor plate, not loose. In order to prevent the long exposure from affecting the work of other workers, the portable grinding turbine can be used to remove the excess steel hinge line, with the outer length of 30cm.

Key control measures for the construction of the anchor cable

1、The anchor site is laid out, and the allowable error in each direction is ± 5cm.

2、Install the drilling rig in place according to the coordinates of the designed hole opening, release the baseline and the anchor cable in the slope direction, and adjust the inclination until the design requirements are met. After locating the rig, check the seat, orientation and inclination of the rig again, and start drilling.

3、The allowable error of the aperture of the anchor cable is ± 5cm.

4、In case of collapse, drilling should be stopped immediately, and solid wall grouting should be conducted after 24 hours.

5、The production of anchor cable should ensure that each steel strand is always evenly arranged, straight, not twisted or cross, rust and oil should be removed, and the mechanical damage and rust pit should be removed.

6、The length of the anchor cable should be determined according to the actual depth of the borehole, allowing an error of ± 2cm, and the anchor cable should be numbered accordingly according to the hole number.

7、The anchor cable should be placed to ensure that the grouting thickness of the anchor cable hole wall is not less than 1cm, the anchor cable should be placed flat and straight, and the tension section should be placed in the center of the anchor hole.

8、Anchor cable grouting cement should be selected above 32.5 ordinary Portland cement, mixing cement mortar should be uniform, and there should be no precipitation when using. The drilling pipe should continue to keep the grouting process continuously and rotate slowly to exit to ensure that the grouting in the hole is dense.

9、Strictly control the water addition and water ash ratio.

10、The tension of the anchor cable should be carried out only after the cement slurry reaches the design strength.

11、The pretensioning equipment shall be calibrated, and the fixture connector shall comply with the relevant regulations.

——Source: First Company Construction Technology

Disclaimer: We respect originality and share it, and appreciate the hard work and creativity of each author. We are committed to protecting the copyright of authors, the sources of content have been marked with the source, only for knowledge dissemination and sharing, no other commercial profit role, if there is any infringement, please contact us to remove.