【Construction Case】SJL-120 rotary jet drilling rig,MJS method rotary jet water stop construction

Browse services

- Petroleum and Gas

- 【Excerpt】High pressure jet grouting construction technology

- 【Excerpt】How to construct slope anchor cable?

- HDL-60S multi-function drilling rig shipped to Singapore

- 【Excerpt】Why do we need to test piles before pile foundation construction?

- We are the one-stop construction problem solver

- 【Holiday arrangement】Dragon Boat Festival

- 【Excerpt】The "Seven-Character Guideline" for Ground Treatment: A Comprehensive Interpretation!

- 【Excerpt】What is the difference between cement mixing pile and high pressure jet pile?

- 【Construction Case】HDL-200C top drive drilling rig for water stopper curtain of overseas dam

- 【Excerpt】What to do with a broken pile

- Holiday arrangement

- Our Drilling Rig: Client Success Story

Stratigraphic Situation

Location (Province): Jiangsu

Location (City): Wuxi

Drilling rig model: SJL-120 rotary spray drilling rig

Drilling tool configuration: Anman 142 series multi-hole drill bit, drill pipe, splitter

Process Type: Water stop by rotary spray

Construction process: MJS method

Ground conditions: 1-4m backfill layer

4-20m clay layer

Construction angle(°):90

Pile diameter (mm): 2000

Hole depth(m):20

Construction techniques

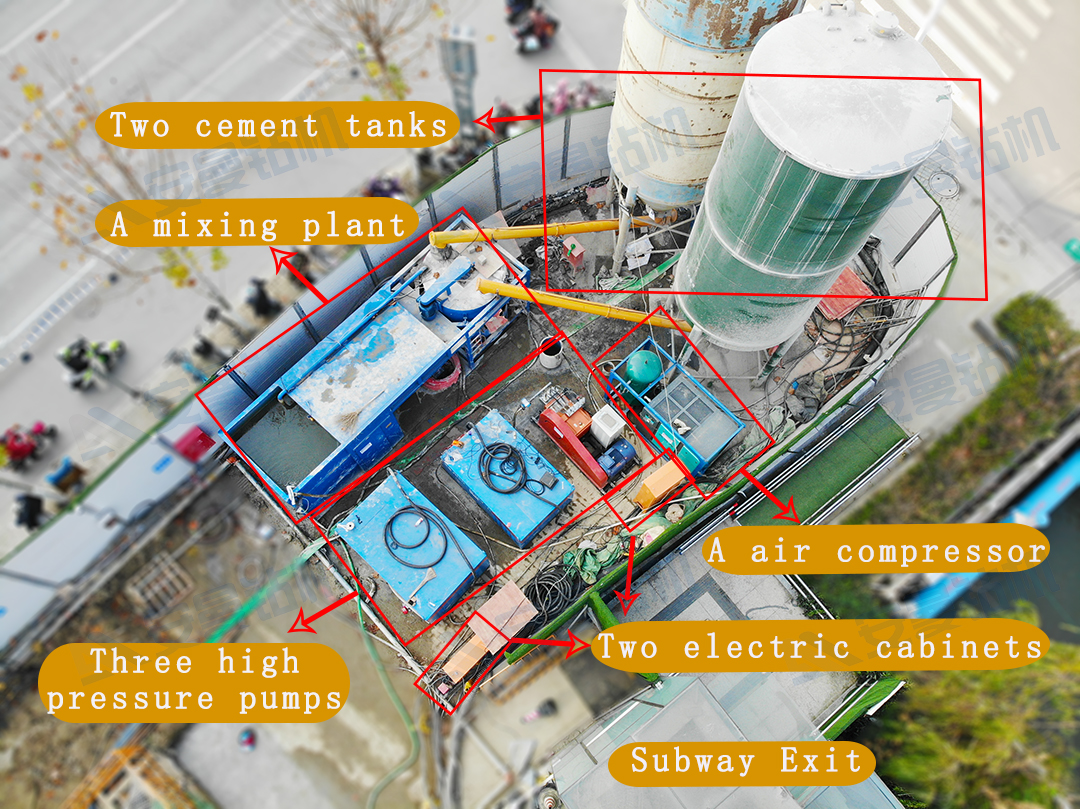

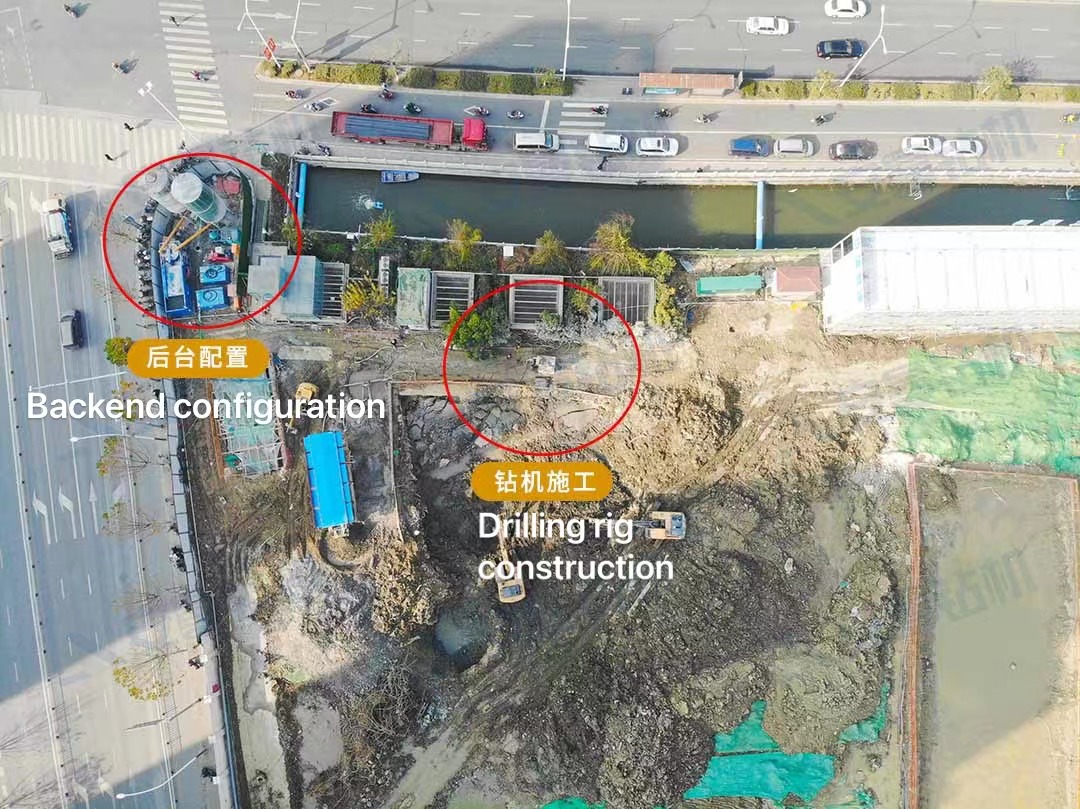

Construction configuration:

One Anman SJL-120 drilling rig

Backstage configuration:

One 230 high-pressure pump

165 high-pressure pump

One 90E high-pressure pump

One 9 cubic meter air compressor

Nozzle selection 2.8

Construction background configuration diagram

1、determine the position of each pile as required.

2、Install a 280mm drill bit for the pilot hole rig to pilot the hole, pay attention to the feed rate during construction to prevent skewing, and dismantle the drill pipe after hitting the required depth.

3、After the SJL-120 drilling rig is installed with the drill bit (internal clamp clamping), align the holes as required, adjust the verticality and brace the legs.

4、test and check whether the high-pressure pump, mixing station, air compressor, nozzle, flow meter, pressure sensor, background data transmitting terminal and drilling rig receiving module display, data recording, etc. are normal.

5、seal the grouting nozzle and cutting water nozzle with transparent tape, connect the drill pipe in turn (pay attention to check the seal when connecting the drill pipe), and finally install the diverter.

Anman engineers on-site guidance

6、Turn on the air compressor, high pressure pump and mixing station. 230 high pressure pump slurry pressure 40Mpa, 90E reverse suction 15Mpa, air pressure 1.0Mpa, 360° swing spraying rotary speed 6r/min, step stroke 30mm/min, pay attention to the change of rotary pressure and slurry return during the construction process, dismantle the drill pipe to clean it in time to prevent plugging the hole.

——Anman drilling rig sales and service: Wang Bing