【Excerpts】Common problems and corrective measures in the construction process

Browse services

- Petroleum and Gas

- 【Excerpt】High pressure jet grouting construction technology

- 【Excerpt】How to construct slope anchor cable?

- HDL-60S multi-function drilling rig shipped to Singapore

- 【Excerpt】Why do we need to test piles before pile foundation construction?

- We are the one-stop construction problem solver

- 【Holiday arrangement】Dragon Boat Festival

- 【Excerpt】The "Seven-Character Guideline" for Ground Treatment: A Comprehensive Interpretation!

- 【Excerpt】What is the difference between cement mixing pile and high pressure jet pile?

- 【Construction Case】HDL-200C top drive drilling rig for water stopper curtain of overseas dam

- 【Excerpt】What to do with a broken pile

- Holiday arrangement

- Our Drilling Rig: Client Success Story

Anti-floating anchor rod is a kind of anti-floating measures of underground structures of construction engineering, which refers to the general term of various pile types that resist the upward displacement of buildings. The anti-floating anchor rod is different from the general foundation pile and has its own unique properties. The biggest difference with the general foundation pile is usually compression pile, the pile bears the building load pressure from the top of the pile to the change of the building load; the anti-floating pile; the force is changed from the pile top to the pile bottom, but the stress mechanism is the opposite.

When the dead weight and soil of the basement of the building can not offset the buoyancy generated by groundwater, the adverse effects of groundwater buoyancy can be eliminated by setting the vertical anti-floating anchor rod, and the stability and safety of the basement can be guaranteed.

① Floating anchor rod force resistance characteristics

For the anti-floating anchor tensile member, one end is anchored in the floor of the building, and the other end is anchored in the bearing layer of the foundation. The force process first transmits the grouting force to the surrounding stable soil through the friction force, so as to form the anti-floating anchor with certain anti-pulling ability, which plays the anti-floating effect of the anti-floating anchor.

In addition to balancing the buoyancy of groundwater, the anti-floating anchor rod can also reinforce the foundation, so as to reduce the deformation and uneven settlement of the foundation.

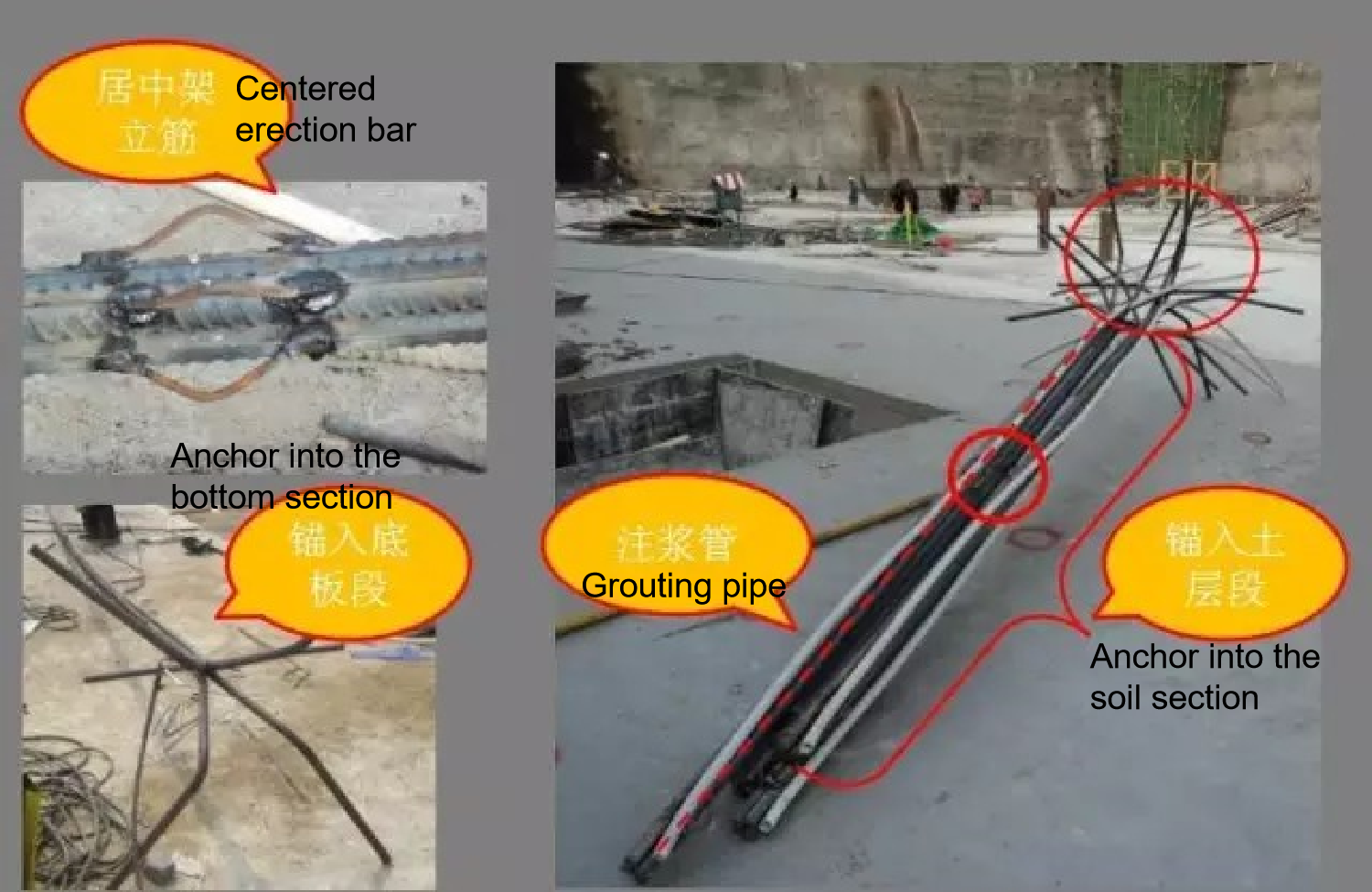

② Anti-floating anchor body

Anti-floating anchor rod: bar body frame vertical bar grouting pipe

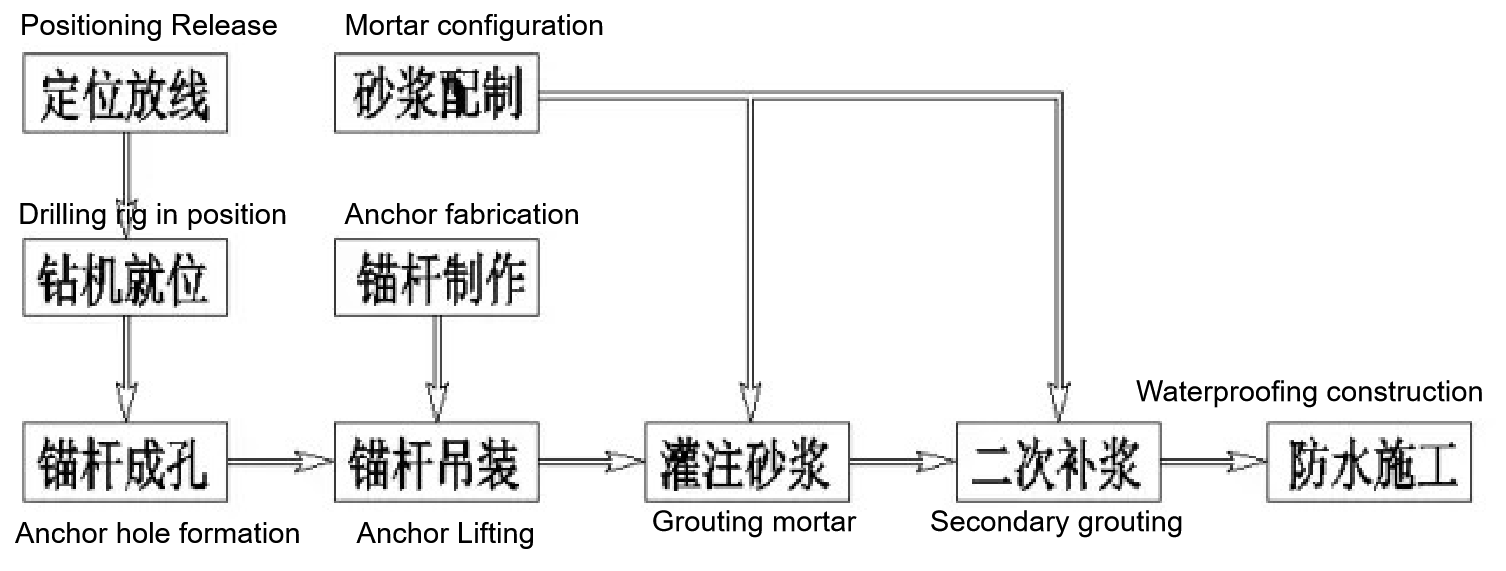

③ Construction technology of anti-floating anchor rod

④ Anti-floating anchor rod construction quality problems

1、The bolt making is prone to problems

① The length of the bolt bottom material straight section is not enough.

② The bending point position and bending Angle are inconsistent with the design drawings.

The qualified anchors shall not be put into use

Measures of making corrections:

When the bolt is processed, the bolt length shall be strictly controlled according to the design requirements, and the straight length of the bolt of each type shall not be lower than the design length.

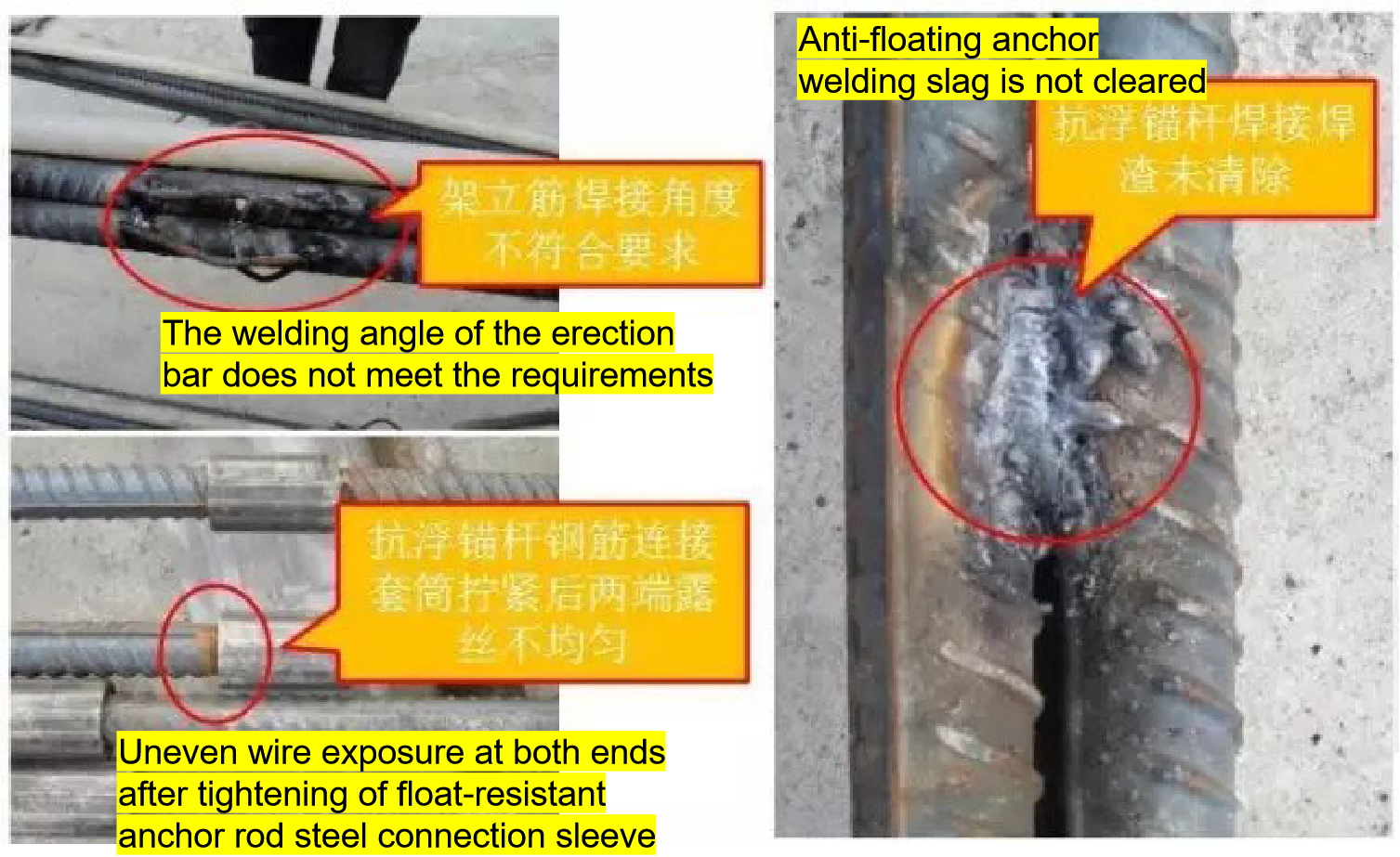

2、The welding quality of the anti-floating anchor rod does not meet the requirements

The welding quality of the anchor bar is poor. After the anchor crane is transported to the site, the anchor bar is easy to fall off and deviate

Quality rectification measures:

The anchor bar should be welded fully, and pay attention to the protection of finished products when lifting. If the anchor rod crane is transported to the site, the site shall be welded twice and the supplementary welding is in place.

Site sample: welding the frame on the anchor rod, strictly according to the sample construction.

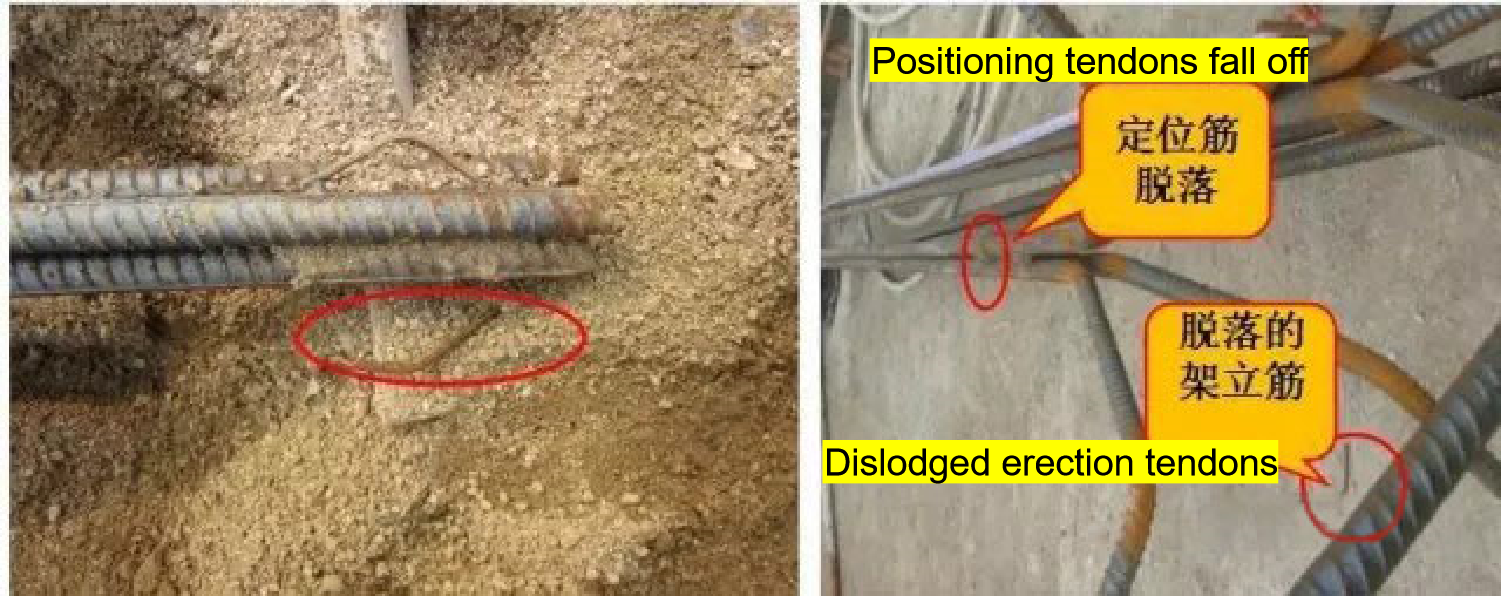

3、The anti-floating anchor rod hole cleaning slag is not timely and rectification situation

Dump cleaning is not timely

Drill slag timely clearance

Quality rectification measures:

After the hole of the anchor hole, the gravel and other garbage generated by the anchor hole around the anchor hole should be cleaned immediately, at least ensure that there is no garbage anchor hole within the anchor hole within 50cm around the anchor hole.

4、The grouting pipe length is too short

The grouting pipe length is too short, which seriously affects the grouting quality

5、The anchor positioning of the anchor rod is not correct

(1)Cause analysis: the anchor positioning of some anchors is not correct or the deviation of the bolt is not taken in time, resulting in serious deviation of the bolt after grouting

The deviation is serious after the bolt grouting

(2)Rectification measures: ensure that the anchor is in the middle. During the grouting process, the anchor should be righted in time. If the anchor is offset after the grouting, check whether the anchor is centered and fixed.

6、the anchor rod standard superior difference

(1)Cause analysis:

A. When the anchor is processed, the anchor bending Angle is not enough, resulting in the warping of the anchor end and the excellent difference of the anchor mark.

B. The machining size of the anchor head part does not meet the requirements. The vertical distance between the horizontal section and the anchor rod starting point is too large.

(2)Rectification measures:

It is required that the bending Angle of the anchor end meets the requirements, and the bending section should not be warped.

The machining size of the anchor head anchor rod is processed strictly in accordance with the design requirements.

7、Grumination and grouting

Grouting : first use steel wire rubber composite high pressure grouting pipe to send the cement mortar to the hole mouth and the high strength PVC grouting pipe inserted into the anchor hole firmly connected, first put the suction mouth of the grouting pump (commonly known as lotus head) into the full cement mortar storage pool, and then start the grouting pump for normal pressure grouting, the grouting pressure is 0.5~1.0Mpa. The grouting starts from the bottom of the hole to facilitate the outlet of the air and sediment. The grouting must be carried out continuously, and the intermittent time can not be too long. Until the slurry overflow of the hole is all cement mortar, the PVC grouting pipe can be slowly withdrawn, and the pipe is pumped at the same time, until all the grouting pipe is pulled out of the hole before the grouting can be stopped.

Pulfilling : after the first grouting final coagulation, check the fullness of the bolt grouting hole and fill the grouting according to the actual situation. After the grouting, the PVC grouting pipe can be slowly drawn out, and the grouting can be pumped out until all the grouting pipe can be stopped.

8、The back layer of the anchor hole grouting is not handled in time after the end

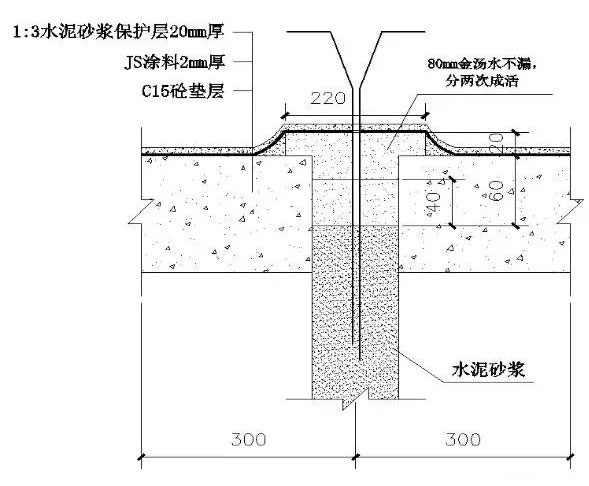

After the grouting of the anchor hole, the 40-thick water unleakage construction surface in the anchor hole is not left out in time, which affects the subsequent waterproof construction progress.

After the grouting of the anchor hole, especially at night grouting construction, the 40 thick water in the anchor hole should be left before the mortar setting on the same day.

9、Water leakage, JS coating waterproof construction

Construction quality requirements without water leakage:

A total of 80 thick, each 40 thick two survive, anchor hole 60 thick and cushion layer, cushion layer above 20 thick, diameter 220

Construction quality requirements of JS coating plaster:

JS coating 2 thick, diameter 600 points two survive, JS coating to apply the base before cleaning, leveling and then construction. If the base pit is uneven, use cement slurry to level.

JS construction should be applied evenly without air bubbles

JS coating film can be waterproof mortar protective layer construction

10、The anchor frame positioning short steel bar out of the waterproof layer

Analysis of causes:

The supporting steel bar welded at the bending part of the anchor rod is not cut out after the anchor rod grouting and the water leakage waterproof construction, resulting in the long supporting steel bar and the water cannot be concealed without leakage, which affects the waterproof effect.

Measures of making corrections:

Remove the support steel bar after the grouting before the waterproof construction.

11、The anchor rod body of the floating slurry

Analysis of causes:

The anchor slurry is not removed before the construction, which affects the subsequent painting of JS soil layer

Quality rectification measures:

Remove the anchor bar floating slurry and paint the JS soil layer again

The protective layer construction shall be carried out after the acceptance of the JS coating

Number the floating anchor after completing the waterproof construction

The large surface view of the antifloating anchor rod

The quality problems that are easy to appear in the construction of the anti-floating anchor have been summarized. As long as each engineer tries to control them and strictly control the quality problems, the construction of the anti-floating anchor is successfully completed according to the quality and quantity.

——

Disclaimer: We respect originality and share it, and appreciate the hard work and creativity of each author. We are committed to protecting the copyright of authors, the sources of content have been marked with the source, only for knowledge dissemination and sharing, no other commercial profit role, if there is any infringement, please contact us to remove.